VHA Advanced Manufacturing

Enhancing Veteran Care with Patient-Matched Solutions

VHA has an ambitious goal: for every Veteran to have access to patient-specific medical

devices and products through advanced manufacturing services. Advanced manufacturing

technologies (i.e., 3D Printing, injection molding, vacuum forming, and laser machining) are

dynamic tools that enhance the supply and specialization of medical devices.

Currently, there are three FDA-registered Advanced Manufacturing Hubs that can 3D Print and

distribute patient-specific products for Veterans. These VAMCs will create products that

deliver the highest value for the lowest cost while driving innovation across the

enterprise.

Advanced Manufacturing Use Cases

Orthotics & Prosthetics

VHA innovators at an FDA-registered advanced manufacturing site used 3D printing to iteratively create a patient-matched hearing enhancement device that is safe, effective, and customized for the Veteran. FDA-registered sites will continue to explore and design devices to help solve unique Veteran challenges.

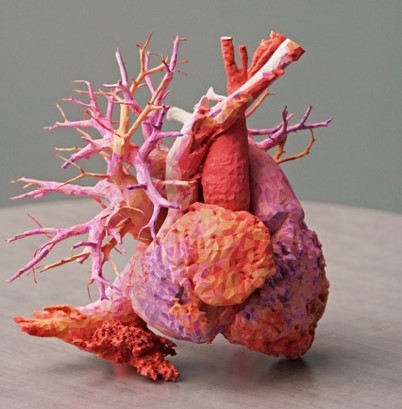

Bioprinting

VHA researchers are working to fabricate 3D printed structures that can support Veteran-specific living cells. VHA innovators believe this technology may one day close the growing gap between supply and demand for organs and tissues.

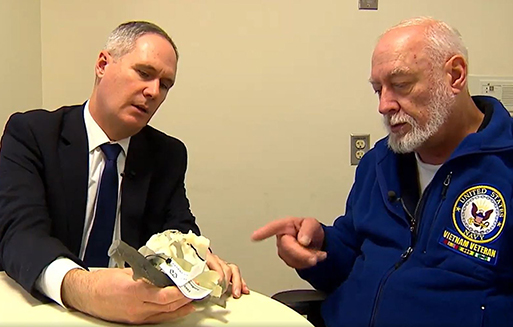

Surgical Planning

Advanced manufacturing allows clinicians and engineers to collaborate on the design and production of custom devices and solutions for Veterans, such as near-exact replicas of anatomic models for surgical planning. Veterans can now visualize clinical solutions in a tangible and interactive way.

Assistive Technologies

VHA innovators are creating patient-specific products to help Veterans perform daily activities that might otherwise be difficult, allowing for renewed independence. Assistive technology specialists continue to collaborate with Veterans on low-tech and high-tech products based on lifestyle preferences.